Amapayipi Ensimbi Yekhabhoni Ehlanganisiwe Evunguzayo Yamapayipi Amanzi Angaphansi Komhlaba

Amanethiwekhi amanzi angaphansi komhlaba ayingxenye ebalulekile yengqalasizinda yanoma yiliphi idolobha noma idolobha. Inesibopho sokuhlinzeka ngamanzi okuphuza ahlanzekile naphephile emakhaya, emabhizinisini nakwezinye izikhungo. Ngaphandle kwezinhlelo zokufaka amapayipi ezinokwethenjelwa, ukufinyelela amanzi ahlanzekile kuzoba sengozini enkulu, okuholela ezingozini zempilo ezingaba khona kanye nokuphazamiseka empilweni yansuku zonke. Ngakho-ke, kubalulekile ukuqinisekisa ukuthi izinto ezisetshenziswa kula mapayipi zisezingeni eliphezulu futhi ziyakwazi ukuhlangabezana nezidingo zokuthuthwa kwamanzi angaphansi komhlaba.

| Ububanzi Bangaphandle Obucacisiwe (D) | Ubukhulu Bodonga Obucacisiwe ngo-mm | Ingcindezi yokuhlola encane kakhulu (Mpa) | ||||||||||

| Ibanga Lensimbi | ||||||||||||

| in | mm | L210(A) | L245(B) | L290(X42) | L320(X46) | L360(X52) | L390(X56) | L415(X60) | L450(X65) | L485(X70) | L555(X80) | |

| 8-5/8 | 219.1 | 5.0 | 5.8 | 6.7 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 |

| 7.0 | 8.1 | 9.4 | 13.9 | 15.3 | 17.3 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 11.5 | 13.4 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 9-5/8 | 244.5 | 5.0 | 5.2 | 6.0 | 10.1 | 11.1 | 12.5 | 13.6 | 14.4 | 15.6 | 16.9 | 19.3 |

| 7.0 | 7.2 | 8.4 | 14.1 | 15.6 | 17.5 | 19.0 | 20.2 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 10.3 | 12.0 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 10-3/4 | 273.1 | 5.0 | 4.6 | 5.4 | 9.0 | 10.1 | 11.2 | 12.1 | 12.9 | 14.0 | 15.1 | 17.3 |

| 7.0 | 6.5 | 7.5 | 12.6 | 13.9 | 15.7 | 17.0 | 18.1 | 19.6 | 20.7 | 20.7 | ||

| 10.0 | 9.2 | 10.8 | 18.1 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 12-3/4 | 323.9 | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.6 |

| 7.0 | 5.5 | 6.5 | 10.7 | 11.8 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.4 | ||

| 10.0 | 7.8 | 9.1 | 15.2 | 16.8 | 18.9 | 20.5 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (325.0) | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.5 | |

| 7.0 | 5.4 | 6.3 | 10.6 | 11.7 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.3 | ||

| 10.0 | 7.8 | 9.0 | 15.2 | 16.7 | 18.8 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 13-3/8 | 339.7 | 5.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.1 | 13.9 |

| 8.0 | 5.9 | 6.9 | 11.6 | 12.8 | 14.4 | 15.6 | 16.6 | 18.0 | 19.4 | 20.7 | ||

| 12.0 | 8.9 | 10.4 | 17.4 | 19.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 14 | 355.6 | 6.0 | 4.3 | 5.0 | 8.3 | 9.2 | 10.3 | 11.2 | 11.9 | 12.9 | 13.9 | 15.9 |

| 8.0 | 5.7 | 6.6 | 11.1 | 12.2 | 13.8 | 14.9 | 15.9 | 17.2 | 18.6 | 20.7 | ||

| 12.0 | 8.5 | 9.9 | 16.6 | 18.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (377.0) | 6.0 | 4.0 | 4.7 | 7.8 | 8.6 | 9.7 | 10.6 | 11.2 | 12.2 | 13.1 | 15.0 | |

| 8.0 | 5.3 | 6.2 | 10.5 | 11.5 | 13.0 | 14.1 | 15.0 | 16.2 | 17.5 | 20.0 | ||

| 12.0 | 8.0 | 9.4 | 15.7 | 17.3 | 19.5 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 16 | 406.4 | 6.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.2 | 13.9 |

| 8.0 | 5.0 | 5.8 | 9.7 | 10.7 | 12.0 | 13.1 | 13.9 | 15.1 | 16.2 | 18.6 | ||

| 12.0 | 7.4 | 8.7 | 14.6 | 16.1 | 18.1 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (426.0) | 6.0 | 3.5 | 4.1 | 6.9 | 7.7 | 8.6 | 9.3 | 9.9 | 10.8 | 11.6 | 13.3 | |

| 8.0 | 4.7 | 5.5 | 9.3 | 10.2 | 11.5 | 12.5 | 13.2 | 14.4 | 15.5 | 17.7 | ||

| 12.0 | 7.1 | 8.3 | 13.9 | 15.3 | 17.2 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 18 | 457.0 | 6.0 | 3.3 | 3.9 | 6.5 | 7.1 | 8.0 | 8.7 | 9.3 | 10.0 | 10.8 | 12.4 |

| 8.0 | 4.4 | 5.1 | 8.6 | 9.5 | 10.7 | 11.6 | 12.4 | 13.4 | 14.4 | 16.5 | ||

| 12.0 | 6.6 | 7.7 | 12.9 | 14.3 | 16.1 | 17.4 | 18.5 | 20.1 | 20.7 | 20.7 | ||

| 20 | 508.0 | 6.0 | 3.0 | 3.5 | 6.2 | 6.8 | 7.7 | 8.3 | 8.8 | 9.6 | 10.3 | 11.8 |

| 8.0 | 4.0 | 4.6 | 8.2 | 9.1 | 10.2 | 11.1 | 11.8 | 12.8 | 13.7 | 15.7 | ||

| 12.0 | 6.0 | 6.9 | 12.3 | 13.6 | 15.3 | 16.6 | 17.6 | 19.1 | 20.6 | 20.7 | ||

| 16.0 | 7.9 | 9.3 | 16.4 | 18.1 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (529.0) | 6.0 | 2.9 | 3.3 | 5.9 | 6.5 | 7.3 | 8.0 | 8.5 | 9.2 | 9.9 | 11.3 | |

| 9.0 | 4.3 | 5.0 | 8.9 | 9.8 | 11.0 | 11.9 | 12.7 | 13.8 | 14.9 | 17.0 | ||

| 12.0 | 5.7 | 6.7 | 11.8 | 13.1 | 14.7 | 15.9 | 16.9 | 18.4 | 19.8 | 20.7 | ||

| 14.0 | 6.7 | 7.8 | 13.8 | 15.2 | 17.1 | 18.6 | 19.8 | 20.7 | 20.7 | 20.7 | ||

| 16.0 | 7.6 | 8.9 | 15.8 | 17.4 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22 | 559.0 | 6.0 | 2.7 | 3.2 | 5.6 | 6.2 | 7.0 | 7.5 | 8.0 | 8.7 | 9.4 | 10.7 |

| 9.0 | 4.1 | 4.7 | 8.4 | 9.3 | 10.4 | 11.3 | 12.0 | 13.0 | 14.1 | 16.1 | ||

| 12.0 | 5.4 | 6.3 | 11.2 | 12.4 | 13.9 | 15.1 | 16.0 | 17.4 | 18.7 | 20.7 | ||

| 14.0 | 6.3 | 7.4 | 13.1 | 14.4 | 16.2 | 17.6 | 18.7 | 20.3 | 20.7 | 20.7 | ||

| 19.1 | 8.6 | 10.0 | 17.8 | 19.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22.2 | 10.0 | 11.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 24 | 610.0 | 6.0 | 2.5 | 2.9 | 5.1 | 5.7 | 6.4 | 6.9 | 7.3 | 8.0 | 8.6 | 9.8 |

| 9.0 | 3.7 | 4.3 | 7.7 | 8.5 | 9.6 | 10.4 | 11.0 | 12.0 | 12.9 | 14.7 | ||

| 12.0 | 5.0 | 5.8 | 10.3 | 11.3 | 12.7 | 13.8 | 14.7 | 15.9 | 17.2 | 19.7 | ||

| 14.0 | 5.8 | 6.8 | 12.0 | 13.2 | 14.9 | 16.1 | 17.1 | 18.6 | 20.0 | 20.7 | ||

| 19.1 | 7.9 | 9.1 | 16.3 | 17.9 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.5 | 12.0 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (630.0) | 6.0 | 2.4 | 2.8 | 5.0 | 5.5 | 6.2 | 6.7 | 7.1 | 7.7 | 8.3 | 9.5 | |

| 9.0 | 3.6 | 4.2 | 7.5 | 8.2 | 9.3 | 10.0 | 10.7 | 11.6 | 12.5 | 14.3 | ||

| 12.0 | 4.8 | 5.6 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 | ||

| 16.0 | 6.4 | 7.5 | 13.3 | 14.6 | 16.5 | 17.8 | 19.0 | 20.6 | 20.7 | 20.7 | ||

| 19.1 | 7.6 | 8.9 | 15.8 | 17.5 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.2 | 11.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

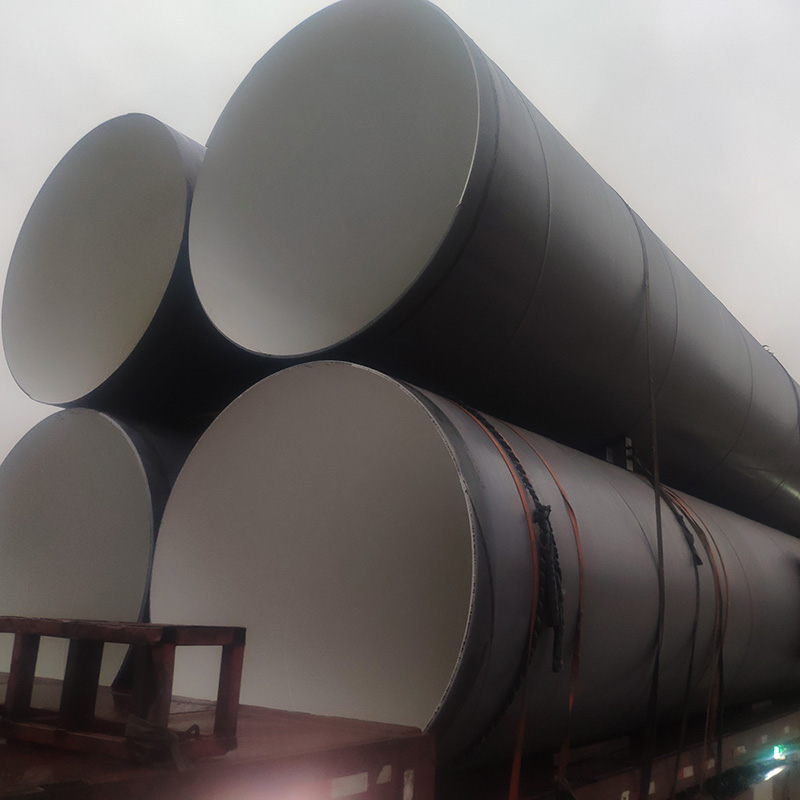

Ipayipi lensimbi yekhabhoni elihlanganisiwe elihlanganisiwe, njenge-S235 JR kanye ne-S235 JRIpayipi lomugqa we-X70 SSAW, kuyisinqumo esithandwayo samapayipi amanzi angaphansi komhlaba ngenxa yokuqina kwawo okuhle kakhulu kanye nokumelana nokugqwala. Amapayipi akhiqizwa kusetshenziswa inqubo yokushisela ejikelezayo, okuqinisekisa ukuthi aqinile futhi isakhiwo siyakwazi ukumelana nezingcindezi kanye nezici zemvelo ezihlobene nokuthuthwa kwamanzi angaphansi komhlaba. Ngaphezu kwalokho, lawa mapayipi akhiwe ngensimbi yekhabhoni esezingeni eliphezulu ukuze aqine futhi ahlale isikhathi eside, okwenza abe ukukhetha okuthembekile kwezinhlelo zokusabalalisa amanzi zesikhathi eside.

Enye yezinzuzo eziyinhloko zokusebenzisaamapayipi ensimbi yekhabhoni ahlanganisiwe ajikelezayoUkuthuthwa kwamanzi angaphansi komhlaba ukumelana kwawo nokugqwala okuphezulu. Amapayipi angaphansi komhlaba ahlala evezwa umswakama nezinye izici zemvelo, okungabangela ukuthi izinto zendabuko ezifana nokhonkolo noma i-PVC zigqwale futhi ziwohloke. Kodwa-ke, amapayipi ensimbi yekhabhoni amelana kakhulu nokugqwala, okuqinisekisa ukuthi agcina ubuqotho besakhiwo sawo ngokuhamba kwesikhathi. Lokhu kumelana nokugqwala kunciphisa kakhulu isidingo sokulungiswa nokufakwa esikhundleni, ekugcineni konga izindleko zesistimu yamanzi.

Ngaphezu kwalokho, amandla nokuqina kwepayipi lensimbi yekhabhoni elihlanganisiwe elijikelezayo kwenza libe yindawo ekahle kakhulu yokufakwa ngaphansi komhlaba. Lawa mapayipi ayakwazi ukumelana nengcindezi yangaphandle evela enhlabathini nakwezinye izinto ezingaphansi komhlaba, okuqinisekisa ukuthi ahlala ehlanzekile futhi esebenza impilo yawo yonke. Ngaphezu kwalokho, ukwakhiwa kwawo kanye nezindawo zangaphakathi ezibushelelezi kunciphisa ingozi yokuvinjelwa noma ukuvuza, okwandisa ukuthembeka nokusebenza kahle kokuthuthwa kwamanzi angaphansi komhlaba.

Ngokufigqiwe,amapayipi amanzi angaphansi komhlabaziyingxenye ebalulekile yengqalasizinda yesimanje, futhi ukukhetha izinto ezisetshenziswa kula mapayipi kubalulekile ekusebenzeni kwawo nasekuphileni kwawo isikhathi eside. Ipayipi lensimbi yekhabhoni elihlanganisiwe elihlanganisiwe, njengepayipi lomugqa le-S235 JR kanye ne-X70 SSAW, linikeza izinzuzo eziningi zokuthuthwa kwamanzi angaphansi komhlaba, okuhlanganisa ukuqina okuphezulu, ukumelana nokugqwala kanye namandla aphezulu. Ngokusebenzisa la mapayipi asezingeni eliphezulu, izinhlelo zamanzi zingaqinisekisa ukulethwa kwamanzi okuthembekile nokuphumelelayo emiphakathini ngenkathi kunciphisa isidingo sokulungiswa nokufakwa esikhundleni.