I-Spiral Welded Carbon Steel Pipes For Underground Water Pipelines

Amanethiwekhi amanzi angaphansi ayingxenye ebalulekile yanoma yiliphi idolobha noma ingqalasizinda yedolobha.Inesibopho sokuhlinzeka ngamanzi okuphuza ahlanzekile naphephile emakhaya, amabhizinisi nezinye izikhungo.Ngaphandle kwezinhlelo zamapayipi ezithembekile, ukutholakala kwamanzi ahlanzekile kuzoba sengozini enkulu, okuholela ezingozini zempilo ezingase zibe khona kanye nokuphazamiseka kokuphila kwansuku zonke.Ngakho-ke, kubalulekile ukuqinisekisa ukuthi izinto ezisetshenziswa kulawa mapayipi zisezingeni eliphezulu futhi ziyakwazi ukuhlangabezana nezidingo zokuthutha emanzini angaphansi komhlaba.

| Ububanzi Bangaphandle Ecacisiwe (D) | Ubukhulu Bodonga Olucacisiwe ngo-mm | Ingcindezi yokuhlola encane (Mpa) | ||||||||||

| Ibanga Lensimbi | ||||||||||||

| in | mm | I-L210(A) | I-L245(B) | I-L290(X42) | I-L320(X46) | I-L360(X52) | I-L390(X56) | I-L415(X60) | I-L450(X65) | I-L485(X70) | I-L555(X80) | |

| 8-5/8 | 219.1 | 5.0 | 5.8 | 6.7 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 |

| 7.0 | 8.1 | 9.4 | 13.9 | 15.3 | 17.3 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 11.5 | 13.4 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 9-5/8 | 244.5 | 5.0 | 5.2 | 6.0 | 10.1 | 11.1 | 12.5 | 13.6 | 14.4 | 15.6 | 16.9 | 19.3 |

| 7.0 | 7.2 | 8.4 | 14.1 | 15.6 | 17.5 | 19.0 | 20.2 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 10.3 | 12.0 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 10-3/4 | 273.1 | 5.0 | 4.6 | 5.4 | 9.0 | 10.1 | 11.2 | 12.1 | 12.9 | 14.0 | 15.1 | 17.3 |

| 7.0 | 6.5 | 7.5 | 12.6 | 13.9 | 15.7 | 17.0 | 18.1 | 19.6 | 20.7 | 20.7 | ||

| 10.0 | 9.2 | 10.8 | 18.1 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 12-3/4 | 323.9 | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.6 |

| 7.0 | 5.5 | 6.5 | 10.7 | 11.8 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.4 | ||

| 10.0 | 7.8 | 9.1 | 15.2 | 16.8 | 18.9 | 20.5 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (325.0) | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.5 | |

| 7.0 | 5.4 | 6.3 | 10.6 | 11.7 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.3 | ||

| 10.0 | 7.8 | 9.0 | 15.2 | 16.7 | 18.8 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 13-3/8 | 339.7 | 5.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.1 | 13.9 |

| 8.0 | 5.9 | 6.9 | 11.6 | 12.8 | 14.4 | 15.6 | 16.6 | 18.0 | 19.4 | 20.7 | ||

| 12.0 | 8.9 | 10.4 | 17.4 | 19.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 14 | 355.6 | 6.0 | 4.3 | 5.0 | 8.3 | 9.2 | 10.3 | 11.2 | 11.9 | 12.9 | 13.9 | 15.9 |

| 8.0 | 5.7 | 6.6 | 11.1 | 12.2 | 13.8 | 14.9 | 15.9 | 17.2 | 18.6 | 20.7 | ||

| 12.0 | 8.5 | 9.9 | 16.6 | 18.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (377.0) | 6.0 | 4.0 | 4.7 | 7.8 | 8.6 | 9.7 | 10.6 | 11.2 | 12.2 | 13.1 | 15.0 | |

| 8.0 | 5.3 | 6.2 | 10.5 | 11.5 | 13.0 | 14.1 | 15.0 | 16.2 | 17.5 | 20.0 | ||

| 12.0 | 8.0 | 9.4 | 15.7 | 17.3 | 19.5 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 16 | 406.4 | 6.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.2 | 13.9 |

| 8.0 | 5.0 | 5.8 | 9.7 | 10.7 | 12.0 | 13.1 | 13.9 | 15.1 | 16.2 | 18.6 | ||

| 12.0 | 7.4 | 8.7 | 14.6 | 16.1 | 18.1 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (426.0) | 6.0 | 3.5 | 4.1 | 6.9 | 7.7 | 8.6 | 9.3 | 9.9 | 10.8 | 11.6 | 13.3 | |

| 8.0 | 4.7 | 5.5 | 9.3 | 10.2 | 11.5 | 12.5 | 13.2 | 14.4 | 15.5 | 17.7 | ||

| 12.0 | 7.1 | 8.3 | 13.9 | 15.3 | 17.2 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 18 | 457.0 | 6.0 | 3.3 | 3.9 | 6.5 | 7.1 | 8.0 | 8.7 | 9.3 | 10.0 | 10.8 | 12.4 |

| 8.0 | 4.4 | 5.1 | 8.6 | 9.5 | 10.7 | 11.6 | 12.4 | 13.4 | 14.4 | 16.5 | ||

| 12.0 | 6.6 | 7.7 | 12.9 | 14.3 | 16.1 | 17.4 | 18.5 | 20.1 | 20.7 | 20.7 | ||

| 20 | 508.0 | 6.0 | 3.0 | 3.5 | 6.2 | 6.8 | 7.7 | 8.3 | 8.8 | 9.6 | 10.3 | 11.8 |

| 8.0 | 4.0 | 4.6 | 8.2 | 9.1 | 10.2 | 11.1 | 11.8 | 12.8 | 13.7 | 15.7 | ||

| 12.0 | 6.0 | 6.9 | 12.3 | 13.6 | 15.3 | 16.6 | 17.6 | 19.1 | 20.6 | 20.7 | ||

| 16.0 | 7.9 | 9.3 | 16.4 | 18.1 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (529.0) | 6.0 | 2.9 | 3.3 | 5.9 | 6.5 | 7.3 | 8.0 | 8.5 | 9.2 | 9.9 | 11.3 | |

| 9.0 | 4.3 | 5.0 | 8.9 | 9.8 | 11.0 | 11.9 | 12.7 | 13.8 | 14.9 | 17.0 | ||

| 12.0 | 5.7 | 6.7 | 11.8 | 13.1 | 14.7 | 15.9 | 16.9 | 18.4 | 19.8 | 20.7 | ||

| 14.0 | 6.7 | 7.8 | 13.8 | 15.2 | 17.1 | 18.6 | 19.8 | 20.7 | 20.7 | 20.7 | ||

| 16.0 | 7.6 | 8.9 | 15.8 | 17.4 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22 | 559.0 | 6.0 | 2.7 | 3.2 | 5.6 | 6.2 | 7.0 | 7.5 | 8.0 | 8.7 | 9.4 | 10.7 |

| 9.0 | 4.1 | 4.7 | 8.4 | 9.3 | 10.4 | 11.3 | 12.0 | 13.0 | 14.1 | 16.1 | ||

| 12.0 | 5.4 | 6.3 | 11.2 | 12.4 | 13.9 | 15.1 | 16.0 | 17.4 | 18.7 | 20.7 | ||

| 14.0 | 6.3 | 7.4 | 13.1 | 14.4 | 16.2 | 17.6 | 18.7 | 20.3 | 20.7 | 20.7 | ||

| 19.1 | 8.6 | 10.0 | 17.8 | 19.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22.2 | 10.0 | 11.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 24 | 610.0 | 6.0 | 2.5 | 2.9 | 5.1 | 5.7 | 6.4 | 6.9 | 7.3 | 8.0 | 8.6 | 9.8 |

| 9.0 | 3.7 | 4.3 | 7.7 | 8.5 | 9.6 | 10.4 | 11.0 | 12.0 | 12.9 | 14.7 | ||

| 12.0 | 5.0 | 5.8 | 10.3 | 11.3 | 12.7 | 13.8 | 14.7 | 15.9 | 17.2 | 19.7 | ||

| 14.0 | 5.8 | 6.8 | 12.0 | 13.2 | 14.9 | 16.1 | 17.1 | 18.6 | 20.0 | 20.7 | ||

| 19.1 | 7.9 | 9.1 | 16.3 | 17.9 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.5 | 12.0 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (630.0) | 6.0 | 2.4 | 2.8 | 5.0 | 5.5 | 6.2 | 6.7 | 7.1 | 7.7 | 8.3 | 9.5 | |

| 9.0 | 3.6 | 4.2 | 7.5 | 8.2 | 9.3 | 10.0 | 10.7 | 11.6 | 12.5 | 14.3 | ||

| 12.0 | 4.8 | 5.6 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 | ||

| 16.0 | 6.4 | 7.5 | 13.3 | 14.6 | 16.5 | 17.8 | 19.0 | 20.6 | 20.7 | 20.7 | ||

| 19.1 | 7.6 | 8.9 | 15.8 | 17.5 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.2 | 11.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

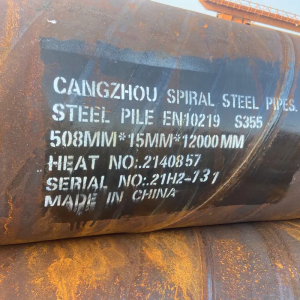

Spiral ashiselwe carbon steel pipe, ezifana S235 JR kanyeIpayipi lomugqa we-X70 SSAW, kuyisinqumo esithandwayo samapayipi amanzi angaphansi komhlaba ngenxa yokuqina kwawo okuhle kakhulu nokumelana nokugqwala.Amapayipi akhiqizwa kusetshenziswa inqubo ye-spiral welding, eqinisekisa ukuthi iqinile futhi isakhiwo esikwazi ukumelana nezingcindezi kanye nezici zemvelo ezihlobene nokuthuthwa kwamanzi angaphansi komhlaba.Ukwengeza, lawa mapayipi akhiwe nge-carbon steel yekhwalithi ephezulu ukuze aqine futhi aphile isikhathi eside, okwenza kube ukukhetha okuthembekile kwezinhlelo zesikhathi eside zokusabalalisa amanzi.

Enye yezinzuzo eziyinhloko zokusebenzisaspiral ashiselwe carbon steel amapayipingoba ukuthuthwa kwamanzi angaphansi komhlaba kuwukumelana nokugqwala kwawo okuphezulu.Amapayipi angaphansi komhlaba ahlala echayeke kumswakama nezinye izici zemvelo, ezingabangela izinto zendabuko ezifana nokhonkolo noma i-PVC ukuthi zigqwale futhi ziwohloke.Kodwa-ke, amapayipi e-carbon steel amelana kakhulu nokugqwala, aqinisekisa ukuthi agcina ubuqotho bawo besakhiwo ngokuhamba kwesikhathi.Lokhu kumelana nokugqwala kunciphisa kakhulu isidingo sokunakekelwa nokushintshwa, ekugcineni konga izindleko zesistimu yamanzi.

Ukwengeza, amandla nokuqina kwepayipi lensimbi yensimbi elivunguzayo kuyenza ibe ilungele ukufakwa ngaphansi komhlaba.Lawa mapayipi ayakwazi ukumelana nokucindezela kwangaphandle okuvela enhlabathini nakwezinye izakhi ezingaphansi komhlaba, ukuqinisekisa ukuthi ahlala eqinile futhi esebenza kukho konke ukuphila kwawo kwenkonzo.Ukwengeza, ukwakhiwa kwayo kanye nezindawo ezibushelelezi zangaphakathi kunciphisa ubungozi bokuvinjwa noma ukuvuza, kuqhubeke kwandise ukuthembeka nokusebenza kahle kokuthuthwa kwamanzi angaphansi komhlaba.

Ngokufigqiwe,amapayipi amanzi angaphansi komhlabaziyingxenye ebalulekile yengqalasizinda yesimanje, futhi ukukhethwa kwezinto ezisetshenziswa kulawa mapayipi kubalulekile ekusebenzeni kwawo nokuphila isikhathi eside.Ipayipi le-Spiral welded carbon steel, njengepayipi lomugqa we-S235 JR kanye ne-X70 SSAW, linikeza izinzuzo eziningi zokuhamba kwamanzi angaphansi komhlaba, okuhlanganisa ukuqina okuphakeme, ukumelana nokugqwala namandla aphezulu.Ngokusebenzisa la mapayipi ekhwalithi ephezulu, izinhlelo zamanzi zingaqinisekisa ukulethwa kwamanzi okuthembekile, okuphumelelayo emiphakathini kuyilapho kunciphisa isidingo sokunakekelwa nokushintshwa.