Ukusebenza Kahle Kohlelo Lokuphayipha Nokuphepha Ngamapayipi Ensimbi Ejikelezayo e-S235 JR

Isingeniso:

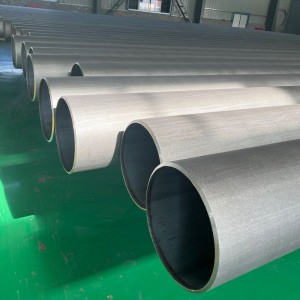

Emphakathini wanamuhla, ukuthuthwa kahle koketshezi namagesi kubalulekile ezimbonini eziningi. Esinye sezici ezibalulekile ekuqinisekiseni ukusebenza kahle kwemikhiqizo yakho.uhlelo lomugqa wamapayipiukukhetha amapayipi afanele. Phakathi kwezinketho ezahlukahlukene ezitholakalayo,Ipayipi Lensimbi Ejikelezayo le-S235 JRkuyisinqumo esithembekile ngenxa yekhwalithi yaso ephezulu. Le bhulogi ihlose ukuhlola izinzuzo zokusebenzisa ipayipi lensimbi elijikelezayo le-S235 JR ezinhlelweni zamapayipi, igxile esakhiweni sayo esihlanganisiwe esijikelezayo.

Impahla Yomshini

| ibanga lensimbi | amandla amancane okukhiqiza | Amandla okudonsa | Ukwandiswa okuncane | Amandla amancane omthelela | ||||

| Ubukhulu obucacisiwe | Ubukhulu obucacisiwe | Ubukhulu obucacisiwe | ekushiseni kokuhlolwa kwe- | |||||

| 16 | >16≤40 | <3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

Ukwakheka Kwamakhemikhali

| Ibanga lensimbi | Uhlobo lokususa i-oxidation a | % ngobuningi, ubuningi | ||||||

| Igama lensimbi | Inombolo yensimbi | C | C | Si | Mn | P | S | Nb |

| S235JRH | 1.0039 | FF | 0,17 | — | 1,40 | 0,040 | 0,040 | 0.009 |

| S275J0H | 1.0149 | FF | 0,20 | — | 1,50 | 0,035 | 0,035 | 0,009 |

| S275J2H | 1.0138 | FF | 0,20 | — | 1,50 | 0,030 | 0,030 | — |

| S355J0H | 1.0547 | FF | 0,22 | 0,55 | 1,60 | 0,035 | 0,035 | 0,009 |

| S355J2H | 1.0576 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| S355K2H | 1.0512 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| a. Indlela yokususa i-oxidation ichazwa kanje: FF: Insimbi ebulewe ngokuphelele equkethe izinto zokubopha i-nitrogen ngamanani anele ukubopha i-nitrogen etholakalayo (isb. ubuncane be-0,020% iyonke i-Al noma i-0,015% i-Al encibilikayo). b. Inani eliphezulu le-nitrogen alisebenzi uma ukwakheka kwamakhemikhali kubonisa okuqukethwe okungenani kwe-Al okungu-0,020% kanye nesilinganiso esincane se-Al/N esingu-2:1, noma uma kukhona ezinye izinto ezibophayo ze-N ezanele. Izinto ezibophayo ze-N kufanele ziqoshwe kuDokhumenti Yokuhlola. | ||||||||

Ukuhlolwa Kwamanzi

Ubude bepayipi ngalinye kufanele buhlolwe ngumenzi ngengcindezi ye-hydrostatic ezokhiqiza odongeni lwepayipi ukucindezeleka okungaphansi kuka-60% wamandla amancane okukhiqiza ashiwo ekushiseni kwegumbi. Ukucindezela kuzonqunywa yi-equation elandelayo:

P=2St/D

Izinguquko Ezivumelekile Ezisindweni Nasezilinganisweni

Ubude bepayipi ngalinye kufanele bulinganiswe ngokwehlukana futhi isisindo salo akumele sihluke ngaphezu kuka-10% noma u-5.5% ngaphansi kwesisindo salo esicatshangelwayo, kubalwe kusetshenziswa ubude balo kanye nesisindo salo ngobude beyunithi ngayinye.

Ububanzi bangaphandle akufanele buhluke ngaphezu kuka-±1% kusuka kububanzi obujwayelekile bangaphandle obubekiwe

Ubukhulu bodonga nganoma yisiphi isikhathi akufanele bube ngaphezu kuka-12.5% ngaphansi kobukhulu bodonga obubekiwe

1. Qonda ipayipi lensimbi elijikelezayo le-S235 JR:

Ipayipi lensimbi elijikelezayo le-S235 JRiyipayipi elihlanganisiwe eliyindilinga elisetshenziswa kabanzi ezinhlelweni zamapayipi. Zenziwe ngensimbi esezingeni eliphezulu ngokuhambisana nezindinganiso zomhlaba wonke, okuqinisekisa ukuqina okuphezulu namandla. Inqubo yokukhiqiza ihilela ukwakheka okujikelezayo kwezinsimbi zensimbi eziqhubekayo, ezibe sezihlanganiswa ubude obufunekayo. Le ndlela yokwakha inikeza amapayipi izinzuzo ezibalulekile ngaphezu kwamapayipi endabuko anomthungo oqondile.

2. Izinzuzo zokwakhiwa kwamapayipi ahlanganisiwe nge-spiral:

Ukwakhiwa kwe-spiral weld ye-S235 JR Spiral Steel Pipe kunikeza izinzuzo eziningi ezinhlelweni zamapayipi. Okokuqala, i-continuous spiral weld seams ithuthukisa ubuqotho besakhiwo sepayipi, okwenza imelane kakhulu nezingcindezi zangaphakathi nezangaphandle. Lesi sakhiwo siphinde siqinisekise ukusatshalaliswa komthwalo ngokulinganayo, kunciphisa ingozi yokwehluleka kwepayipi. Ngaphezu kwalokho, ukuma kwe-spiral kwepayipi kususa isidingo sokuqinisa kwangaphakathi, ngaleyo ndlela kuthuthukisa amakhono okugeleza futhi kunciphise ukulahlekelwa yingcindezi ngesikhathi sokudluliselwa koketshezi. Ubuso obuqhubekayo obungenamthungo bepayipi le-spiral bunciphisa ingozi yokuvuza futhi buthuthukisa ukuphepha nokusebenza kahle kwesistimu yamapayipi.

3. Thuthukisa ukuqina kanye nokuguquguquka:

Ipayipi Lensimbi Ejikelezayo le-S235 JR linikeza ukuqina okuphezulu ngenxa yezinto zokwakha ezisezingeni eliphezulu. Amelana nokugqwala, ukuguguleka kanye nezimo zezulu ezimbi kakhulu, okwenza kube kuhle kakhulu ezinhlotsheni ezahlukene zezicelo okuhlanganisa ukuthuthwa kukawoyela negesi, izinhlelo zamanzi kanye namaphrojekthi engqalasizinda. Ukuguquguquka kwala mapayipi kwenza kube lula ukuwahlela ukuze ahlangabezane nezidingo ezithile zephrojekthi. Ngaphezu kwalokho, kulula ukuwafaka nokunakekela, okwengeza ekukhangeni kwawo futhi kusize ekuholeni ohlelweni lwe-ductwork olusebenzisa imali eningi futhi olusebenzisa isikhathi esiningi.

4. Izinzuzo zemvelo kanye nokusimama kwazo:

Ukushintshela epayipini lensimbi elijikelezayo le-S235 JR ezinhlelweni zamapayipi nakho kungaletha izinzuzo ezinkulu zemvelo. Ukuphila kwazo isikhathi eside kanye nokumelana nokuwohloka kunciphisa isidingo sokufakwa kabusha njalo, okuholela ekukhiqizweni okuphansi kwekhabhoni kanye nokukhiqizwa kwemfucuza okuncane. Ngaphezu kwalokho, ukuphinde kusetshenziswe kwensimbi kwenza la mapayipi abe inketho eqhubekayo ngokuhambisana nezimiso zomnotho ojikelezayo. Ngokusebenzisa amapayipi ensimbi ajikelezayo e-S235 JR, izimboni zingaqinisekisa indlela enobungani nemvelo futhi ethembekile yokuthutha uketshezi, ngaleyo ndlela zikhuthaze ikusasa eliluhlaza.

Isiphetho:

Ukusetshenziswa kwepayipi lensimbi elijikelezayo le-S235 JR ezinhlelweni zamapayipi kunikeza izinzuzo eziningi ezibalulekile, okuhlanganisa ukuqina okuthuthukisiwe, ukuphepha kanye nokusebenza kahle. Isakhiwo esihlanganisiwe esijikelezayo siqinisekisa ubuqotho besakhiwo saso futhi sinikeza ukulethwa koketshezi okuthembekile ezimbonini ezahlukahlukene. Ngokufaka ubuchwepheshe obuthuthukisiwe obufana nabu, sivula indlela yezinhlelo zamapayipi ezizinzile nezithembekile.