Ngenisa

Emkhakheni wokufakwa kwezimboni nokuthuthukiswa kwengqalasizinda, amapayipi ensimbi adlala indima ebalulekile ekuqinisekiseni ukusebenza kahle nokuphila isikhathi eside kwezinhlelo ezihlukahlukene.Phakathi kwezinhlobo ezahlukene zamapayipi ensimbi atholakalayo,spiral ashiselwe carbon steel amapayipibaziwa kabanzi ngamandla abo aphezulu, ukuqina, kanye nokusebenza kahle kwezindleko.Lawa mapayipi awumsebenzi wobuciko wobunjiniyela, ngenxa ye-helical seam welding ephakeme kakhulu kanye nezinqubo zokushisela ezingaphansi kwe-helical ezisetshenziswa ekukhiqizeni kwawo.

Spiral Welded Carbon Steel Pipe: Ukunqoba Ubunzima

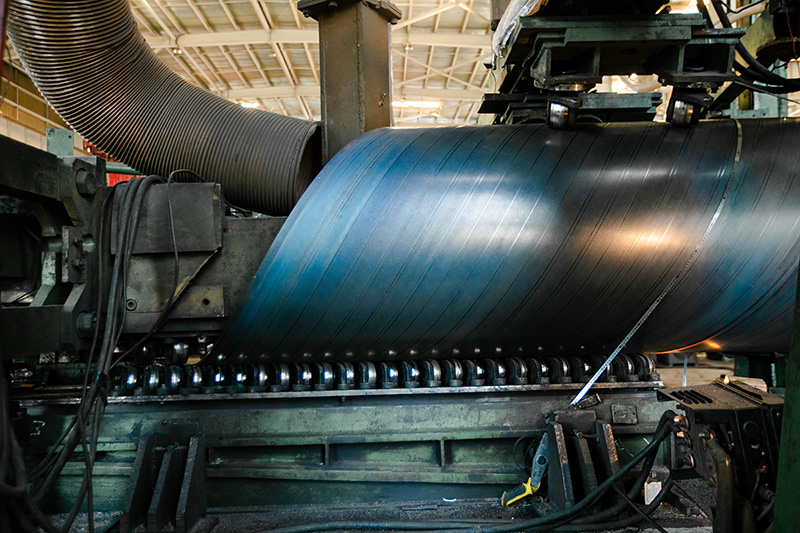

Ipayipi lensimbi le-Spiral welded carbon steel lakhiwa ngokwakha i-strip steel ibe yi-cylindrical spiral shape, emaphethelweni ayo ahlanganiswe ndawonye ngama-seam welds aqhubekayo.Lawa mapayipi ahlukaniswa namapayipi omthungo wendabuko aqondile ngama-helical weld seams athuthukisa ubuqotho besakhiwo kanye nokumelana nokugoba noma ukuguquguquka.

Ubungcweti be-Spiral Seam Welding

I-Spiral seam welding iyinqubo ewumnyombo ekwakhiweni kwamapayipi ensimbi e-spiral welded carbon steel futhi ihilela ukushiselwa okuqhubekayo kwemiphetho yangaphandle nengaphakathi yomugqa wensimbi ogoqiwe.Le ndlela yokushisela engenamthungo iqinisekisa isibopho esingaguquki nesiqinile kulo lonke ubude bepayipi, kunciphisa ubungozi bokuvuza noma ukonakala kwesakhiwo.Kuvunguza umthungo oshiselwe ipayipifuthi igwema isidingo sokuqiniswa okwengeziwe, okwenza ipayipi ingabizi kakhulu ngesikhathi sokufakwa nokugcinwa.

I-Spiral Submerged Arc Welding: Ingcweti Engemuva Kwekhwalithi Ephakeme

I-Helical submerged arc welding(I-HSAW) ubuchwepheshe budlala indima ebalulekile ekuzuzeni ubuqotho obuphezulu besakhiwo samapayipi ensimbi ensimbi e-spiral ashiselwe.Phakathi nale nqubo, i-arc ikhiqizwa ngokuqhubekayo futhi ifakwe ngaphansi kwesendlalelo se-flux.I-arc ibe isetshenziselwa ukuncibilikisa imiphetho yomugqa, ukudala ukuhlangana phakathi kwensimbi encibilikisiwe ne-substrate.Lokhu kuhlangana kwakha i-weld eqinile, yekhwalithi ephezulu enezici ezinhle kakhulu zokusebenza njengokukhuphuka kwamandla okuqinile kanye nokumelana nokugqwala.

Izinzuzo ze-Spiral Welded Carbon Steel Pipe

1. Amandla Nokuqina: Ubuchwepheshe be-Spiral welding bunikeza lawa mapayipi amandla aphakeme okubavumela ukuba babhekane nokucindezela okukhulu, imithwalo esindayo kanye nezimo zezulu ezimbi kakhulu.

2. Ukusebenza kahle kwezindleko: Ukusebenzisa amapayipi ensimbi ane-spiral welded carbon kunganciphisa kakhulu izindleko zephrojekthi ngenxa yokulula kokufaka futhi asikho isidingo sokuqiniswa okwengeziwe.

3. Ukuguquguquka: Amapayipi ensimbi e-Spiral welded carbon steel angenziwa ngobubanzi obuhlukahlukene, ubude nobukhulu obuhlukahlukene, okuwenza afanelekele uhla olubanzi lwezicelo zezimboni.

4. I-Corrosion Resistant: Amashisela ekhwalithi ephezulu e-HSAW aqinisekisa ukuthi la mapayipi anokumelana nokugqwala okuhle kakhulu, andisa impilo yawo yesevisi ngisho nasezimweni ezinzima.

Ekuphetheni

Ubungcweti bokushisela i-spiral seam kanye ne-spiral submerged arc welding kwaguqula ukukhiqizwa kwamapayipi ensimbi.Amandla aphakeme, ukuqina, kanye nokuphumelela kwezindleko zepayipi lensimbi yensimbi ye-spiral welded kuyenza ibe yinto ekhethwayo ezimbonini eziningi.Ikhono labo lokumelana nengcindezi, ukunqoba ukuguquguquka nokumelana nokugqwala kubenza babe isibonelo esihle kakhulu sobunjiniyela.Ngokukhula kwesidingo sengqalasizinda esebenza kahle, enokwethenjelwa, amapayipi ensimbi ashiselwe ku-spiral azodlala indima ebalulekile ekubumbeni ikusasa elisimeme nelixhunyiwe.

Isikhathi sokuthumela: Aug-24-2023