Ngenisa

Emkhakheni wokufakwa kwezimboni kanye nokuthuthukiswa kwengqalasizinda, amapayipi ensimbi adlala indima ebalulekile ekuqinisekiseni ukusebenza kahle kanye nobude bezinhlelo ezahlukene. Phakathi kwezinhlobo ezahlukene zamapayipi ensimbi atholakalayo,amapayipi ensimbi yekhabhoni ahlanganisiwe ajikelezayoaziwa kabanzi ngamandla awo aphezulu, ukuqina, kanye nokusebenza kahle kwezindleko. Lawa mapayipi ayimisebenzi yobuciko yobunjiniyela, ngenxa yokushisela umthungo we-helical osezingeni eliphezulu kanye nezinqubo zokushisela ze-arc ezingaphansi komhlaba ze-helical ezisetshenziswa ekukhiqizweni kwawo.

Ipayipi Lensimbi Yekhabhoni Ehlanganisiwe Ejikelezayo: Ukunqoba Ubunzima

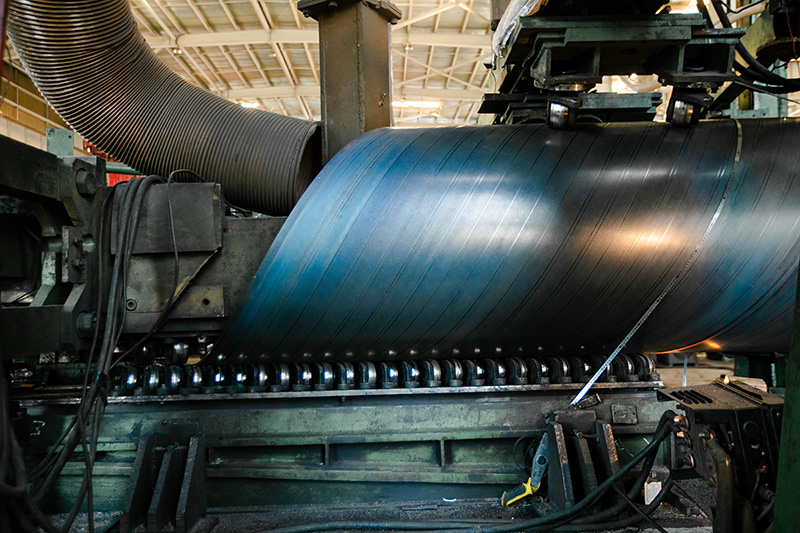

Ipayipi lensimbi yekhabhoni elihlanganisiwe elijikelezayo lakhiwa ngokwakha insimbi eyisiqeshana ibe yisimo esijikelezayo esiyindilinga, imiphetho yayo ihlanganiswa ndawonye ngokushintshwa komthungo okuqhubekayo. Lawa mapayipi ahlukaniswa kumapayipi omthungo aqondile endabuko ngemithungo yokushintshwa komthungo emisha ekhulisa ubuqotho besakhiwo kanye nokumelana nokugoba noma ukuguquka.

Ubuchwepheshe Bokushisela Umthungo Ojikelezayo

Ukushisela umthungo ojikelezayo kuyinqubo eyinhloko ekukhiqizweni kwamapayipi ensimbi yekhabhoni ashiselwe nge-spiral futhi kuhilela ukushisela okuqhubekayo kwemiphetho yangaphandle nengaphakathi yomcu wensimbi ogoqekile. Le ndlela yokushisela engenamthungo iqinisekisa ukubopha okuqinile nokuqhubekayo kulo lonke ubude bepayipi, okunciphisa ingozi yokuvuza noma ukukhubazeka kwesakhiwo.Ipayipi elihlanganisiwe lomthungo ojikelezayofuthi kugwema isidingo sokuqinisa okwengeziwe, okwenza ipayipi libe ngcono kakhulu ngesikhathi sokufakwa nokugcinwa kwalo.

Ukushisela i-Arc Okucwiliswe Nge-Spiral: Ubuchwepheshe Obusemuva Kwekhwalithi Ephakeme

Ukushisela i-arc engaphansi komhlaba nge-helicalUbuchwepheshe (i-HSAW) budlala indima ebalulekile ekufinyeleleni ubuqotho obuphezulu besakhiwo samapayipi ensimbi yekhabhoni ahlanganisiwe nge-spiral. Phakathi nale nqubo, i-arc ikhiqizwa njalo futhi ifakwa ngaphansi kwengqimba yokushintshashintsha. I-arc bese isetshenziswa ukuncibilikisa imiphetho yestrip, okudala ukuhlangana phakathi kwensimbi encibilikisiwe kanye ne-substrate. Lokhu kuhlangana kwakha i-weld eqinile, yekhwalithi ephezulu enezakhiwo ezinhle kakhulu zemishini njengokuqina okuqinile nokumelana nokugqwala.

Izinzuzo ze-Spiral Welded Carbon Steel Pipe

1. Amandla Nokuqina: Ubuchwepheshe bokushisela obujikelezayo bunikeza la mapayipi amandla aphezulu abenza bakwazi ukumelana nokucindezela okuphezulu, imithwalo esindayo kanye nezimo zezulu ezimbi kakhulu.

2. Ukusebenza kahle kwezindleko: Ukusebenzisa amapayipi ensimbi yekhabhoni ahlanganisiwe nge-spiral kunganciphisa kakhulu izindleko zephrojekthi ngenxa yokulula kokufakwa futhi asikho isidingo sokuqinisa okwengeziwe.

3. Ukuguquguquka: Amapayipi ensimbi yekhabhoni ahlanganisiwe nge-Spiral angakhiqizwa ngobubanzi obuhlukahlukene, ubude nobukhulu, okwenza afaneleke ezinhlotsheni eziningi zezimboni.

4. Amelana Nokugqwala: Ama-weld e-HSAW asezingeni eliphezulu aqinisekisa ukuthi la mapayipi anokumelana nokugqwala okuhle kakhulu, okwandisa isikhathi sawo sokusebenza ngisho nasezindaweni ezinzima.

Ekuphetheni

Ubuchwepheshe bokushisela umthungo ojikelezayo kanye nokushisela i-arc engaphansi komhlaba okujikelezayo kwashintsha ukukhiqizwa kwamapayipi ensimbi. Amandla aphezulu, ukuqina, kanye nokusebenza kahle kwepayipi lensimbi yekhabhoni elihlanganisiwe elijikelezayo kwenza kube ukukhetha okuthandwayo kwezimboni eziningi. Amandla abo okubekezelela ukucindezeleka, ukunqoba ukuguquguquka nokumelana nokugqwala kubenza babe isibonelo esihle kakhulu sobunjiniyela. Njengoba isidingo sikhula sengqalasizinda esebenza kahle nethembekile, amapayipi ensimbi yekhabhoni ahlanganisiwe ngokungangabazeki azodlala indima ebalulekile ekwakheni ikusasa elizinzile nelixhumene.

Isikhathi sokuthunyelwe: Agasti-24-2023