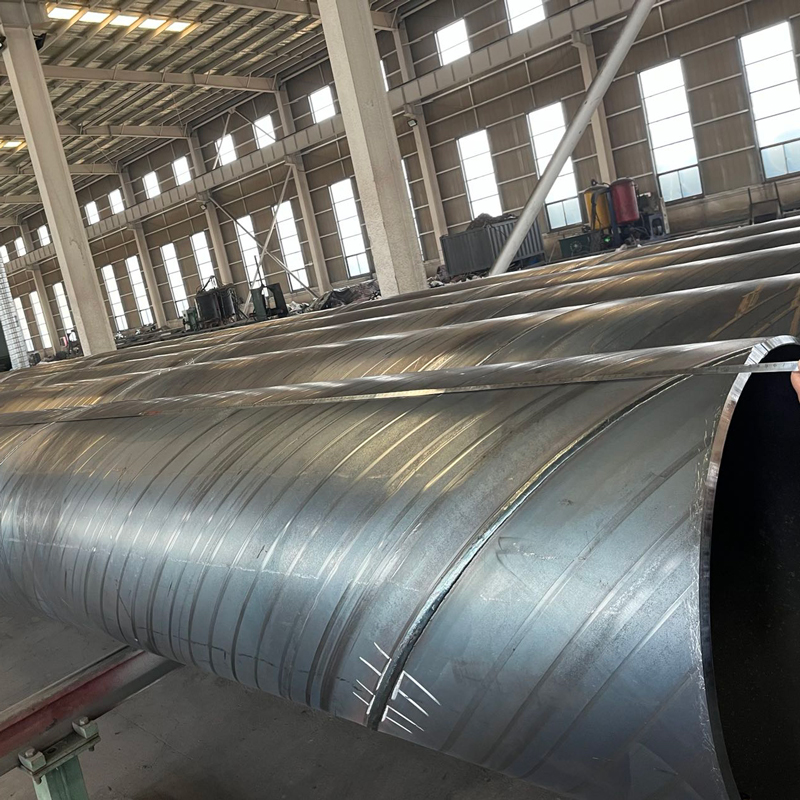

Amapayipi Omugqa we-Api 5l Ibanga B Kuya ku-X70 Od Kusukela ku-219mm Kuya ku-3500mm

Izakhiwo Zemishini Zepayipi Le-SSAW

| ibanga lensimbi | amandla amancane okukhiqiza | amandla amancane okudonsa | Ukwandiswa Okuncane |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| I-X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| I-X56 | 390 | 490 | 19 |

| I-X60 | 415 | 520 | 18 |

| I-X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

Ukwakheka kwamakhemikhali kwamapayipi e-SSAW

| ibanga lensimbi | C | Mn | P | S | I-V+Nb+Ti |

| Ubuningi be-% | Ubuningi be-% | Ubuningi be-% | Ubuningi be-% | Ubuningi be-% | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| I-X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| I-X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| I-X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| I-X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

Ukubekezelelana kweJomethri kwamapayipi e-SSAW

| Ukubekezelelana kwejometri | ||||||||||

| ububanzi bangaphandle | Ubukhulu bodonga | ukuqondisa | ukugqama | isisindo | Ukuphakama okuphezulu kobuhlalu bokushisela | |||||

| D | T | |||||||||

| ≤1422mm | >1422mm | <15mm | ≥15mm | ukuphela kwepayipi 1.5m | ubude obugcwele | umzimba wepayipi | ukuphela kwepayipi | T≤13mm | T >13mm | |

| ±0.5% | njengoba kuvunyelwene | ±10% | ±1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | '+10% | 3.5mm | 4.8mm |

Ukuhlolwa Kwamanzi

Ipayipi kufanele imelane nokuhlolwa kwe-hydrostatic ngaphandle kokuvuza ngomthungo wokushisela noma umzimba wepayipi.

Ama-jointer akudingeki ahlolwe ngamanzi, uma nje izingxenye zamapayipi asetshenziswe ekumaka ama-jointer zihlolwe ngempumelelo ngamanzi ngaphambi kokusebenza kokujoyina.

Ukulandelela:

Kumapayipi e-PSL 1, umenzi kufanele asungule futhi alandele izinqubo ezibhaliwe zokulungisa:

Ubunikazi bokushisa kuze kube yilapho kwenziwa ukuhlolwa ngakunye kwe-chmical okuhlobene futhi kuboniswa ukuhambisana nezidingo ezichaziwe

Ubunikazi beyunithi yokuhlola kuze kube yilapho kwenziwa ukuhlolwa ngakunye okuhlobene kwemishini futhi kuboniswa ukuhambisana nezidingo ezichaziwe

Kumapayipi e-PSL 2, umenzi kufanele asungule futhi alandele izinqubo ezibhaliwe zokugcina ubunikazi bokushisa kanye nobunikazi beyunithi yokuhlola yalelo payipi. Izinqubo ezinjalo zizohlinzeka ngezindlela zokulandelela noma yibuphi ubude bepayipi liye eyunithi yokuhlola efanele kanye nemiphumela yokuhlolwa kwamakhemikhali ehlobene.