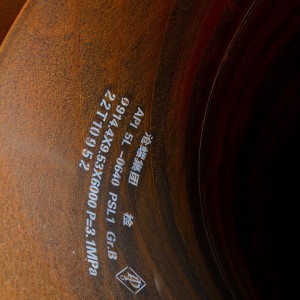

Amapayipi Ensimbi Ahlanganisiwe Ahlanganisiwe Aguquguqukayo

Amapayipi ensimbi ahlanganisiwe ahlanganiswe ngokusonta aklanyelwe ngokukhethekile ukuhlangabezana nezidingo ezahlukahlukene zezimboni ezahlukene futhi asetshenziswa kabanzi ekuthuthweni kukawoyela negesi,inqwaba yepayipiukwakhiwa, izinsika zamabhuloho kanye nezinye izinkambu. Isakhiwo sayo esiyingqayizivele kanye nokusebenza kwayo okuhle kakhulu kwenza kube ukukhetha kokuqala kwezinto zombhobho wendabuko, ngezinzuzo eziyingqayizivele ezithuthukisa ukusebenza kwayo kanye nokusebenza kahle kwayo.

Enye yezinzuzo eziyinhloko ze-ipayipi lensimbi elihlanganisiwe eliyindilingaukusebenza kwayo kahle. Uma kuqhathaniswa namapayipi ensimbi angenamthungo, amapayipi ensimbi ahlanganisiwe ashibhile ukuwakhiqiza ngaphandle kokubeka engcupheni ikhwalithi. Lokhu kwenza imisebenzi ibe ngcono, okwenza kube kuhle kumaphrojekthi adinga inani elikhulu lamapayipi ensimbi ezinhlobonhlobo zezicelo. Ngokunciphisa izindleko, izinkampani zingabela izinsiza ngendlela ephumelelayo, okuholela ekongeni okukhulu kwisabelomali sephrojekthi iyonke.

Impahla Yomshini

| Ibanga 1 | Ibanga lesi-2 | Ibanga lesi-3 | |

| Iphuzu Lokukhiqiza noma amandla okukhiqiza, min, i-Mpa(PSI) | 205(30 000) | 240(35 000) | 310(45 000) |

| Amandla okudonsa, i-min, i-Mpa(PSI) | 345(50 000) | 415(60 000) | 455(66 0000) |

Ngaphezu kwalokho, ukusebenza kahle kokukhiqizaamapayipi ensimbi ajikelezayoiphakeme kakhulu kuneyamapayipi ensimbi angenamthungo. Kumapayipi angenamthungo, inqubo yokukhiqiza ihilela ukukhipha i-billet yensimbi eqinile ngenduku enezimbobo, okuholela enkambisweni yokukhiqiza ehamba kancane futhi eyinkimbinkimbi. Ngokuphambene nalokho, ipayipi elihlanganisiwe elijikelezayo lingakhiqizwa ngobubanzi obukhulu nobude, okuholela ezikhathini zokukhiqiza ezimfushane kanye nokusebenza kahle okwandisiwe. Lokhu kuqinisekisa ukuhlinzekwa okuqhubekayo kwamapayipi asezingeni eliphezulu ngezikhathi ezimfushane, okwenza kube yisisombululo esithembekile nesonga isikhathi sezimboni ezahlukene.

Enye inzuzo ephawulekayo yamapayipi ahlanganisiwe ajikelezayo ukumelana kwawo okuhle kakhulu nengcindezi yangaphandle kanye nokucindezeleka komshini. Ama-weld ahlinzeka ngokuqina okwengeziwe, okuvumela la mapayipi ukuthi amelane nengcindezi ephezulu kunemapayipi angenamthungo. Lesi sici sibaluleke kakhulu ekusetshenzisweni embonini kawoyela negesi, lapho amapayipi ebhekene nengcindezi enkulu yangaphakathi neyangaphandle. Ngokusebenzisa amapayipi ahlanganisiwe ajikelezayo, izinkampani zingaqinisekisa ukuthuthwa okuphephile nokuphumelelayo kwalezi zinsiza ezibalulekile.

Ngaphezu kwalokho, ukuguquguquka kwepayipi elihlanganisiwe elijikelezayo kwenza livumelane nezidingo ezahlukene zokwakha. Lawa mapayipi angenziwa ngokwezifiso ukuze ahlangabezane nezidingo ezithile zephrojekthi, kufaka phakathi ububanzi obuhlukahlukene, ubukhulu nobude. Kungakhathaliseki ukuthi ukufakwa kwezinqwaba zamapayipi noma izinsika zamabhuloho, amapayipi ensimbi ahlanganisiwe ajikelezayo ahlinzeka ngezixazululo ezinhle kakhulu kokubili ukusetshenziswa kwasogwini kanye nolwandle. Ukuqina kwawo okuphezulu kwesakhiwo kuqinisekisa ukusebenza okuhlala isikhathi eside, kunciphisa izindleko zokulungisa futhi kunciphisa isidingo sokufakwa esikhundleni ngaphambi kwesikhathi.

Ngamafuphi, ipayipi elihlanganisiwe elijikelezayo liletha inguquko embonini yamapayipi ensimbi ngokusebenza kwalo okuhle kakhulu kanye nezinzuzo ezibalulekile. Ukusebenza kahle kwayo okuphezulu kwezindleko, ukusebenza kahle kokukhiqiza okuphezulu, ukumelana nengcindezi kanye nokuzivumelanisa nezimo nezinhlelo eziningi kwenza kube ukukhetha kokuqala ekuthuthweni kukawoyela negesi, ukwakhiwa kwezinqwaba zamapayipi, izinsika zamabhuloho nokuningi. Ngomphezulu walo ongenamthungo kanye nemithungo ehlanganisiwe, lo mkhiqizo omusha unikeza ikhambi elithembekile nelihlala isikhathi eside ezimbonini emhlabeni jikelele. Tshala imali kumapayipi ahlanganisiwe ajikelezayo futhi uzwe intuthuko esezingeni eliphezulu kubuchwepheshe bamapayipi ensimbi.