Amandla Nokuthembeka Kwamapayipi Esakhiwo Anezingxenye Ezingenalutho: Ukubuka Okujulile Ipayipi Elihlanganisiwe Le-Arc Elihlanganisiwe Eligobhozayo kanye Nepayipi Lomugqa le-API 5L

Yethula:

Ezweni lokwakha nokuthuthukiswa kwengqalasizinda, ukukhetha izinto ezifanele kubalulekile.Amapayipi esakhiwo esinezingxenye ezingenalutho idlala indima ebalulekile ekuhlinzekeni amandla, ukuqina kanye nokuthembeka kumaphrojekthi ahlukahlukene. Kule bhulogi, sizohlola izici nezinzuzo zezinhlobo ezimbili ezibalulekile zamapayipi okwakha: ipayipi elihlanganisiwe elingaphansi kwe-spiral kanye nepayipi lomugqa we-API 5L.

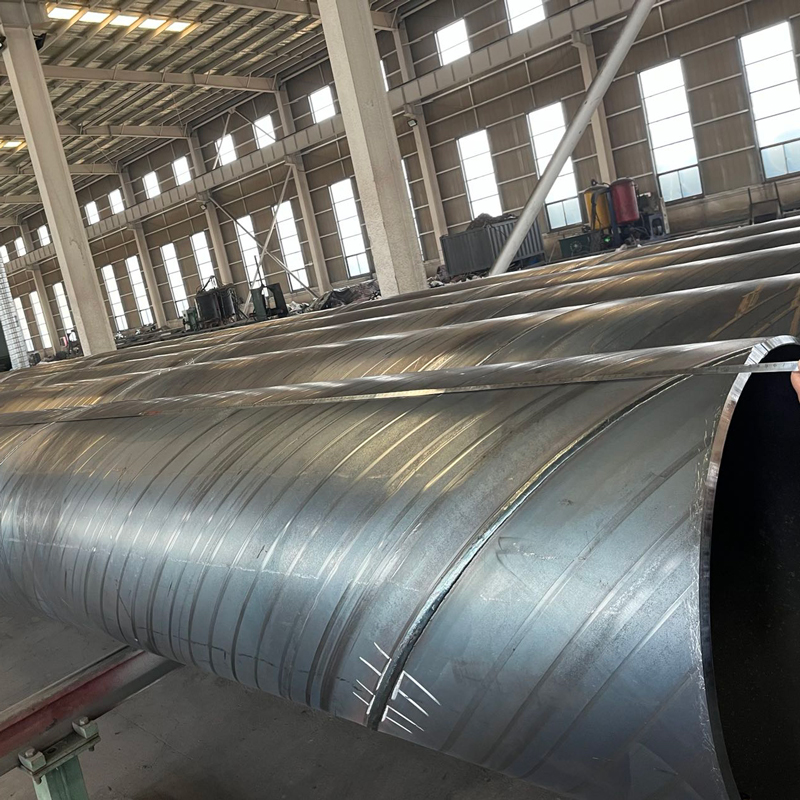

Ipayipi elihlanganisiwe le-arc elingaphansi kwamanzi elihlanganisiwe:

Ipayipi elifakwe i-arc welded (SAW) elicwiliswe emanzini, elaziwa nangokuthi ipayipi le-SSAW, lisetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza. Isici esiyingqayizivele salokhuIpayipi le-SSAW yizithungo zayo ezijikelezayo, ezinikeza amandla amakhulu kanye nomthamo wokuthwala umthwalo uma kuqhathaniswa nezinye izinhlobo zamapayipi. Lo mklamo oyingqayizivele usiza ukusabalalisa ukucindezeleka ngokulinganayo kulo lonke ipayipi, okwenza libe yindawo efanele kumaphrojekthi adinga ubuqotho besakhiwo.

Izakhiwo Zemishini Zepayipi Le-SSAW

| ibanga lensimbi | amandla amancane okukhiqiza | amandla amancane okudonsa | Ukwandiswa Okuncane |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| I-X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| I-X56 | 390 | 490 | 19 |

| I-X60 | 415 | 520 | 18 |

| I-X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

Ukwakheka kwamakhemikhali kwamapayipi e-SSAW

| ibanga lensimbi | C | Mn | P | S | I-V+Nb+Ti |

| Ubuningi be-% | Ubuningi be-% | Ubuningi be-% | Ubuningi be-% | Ubuningi be-% | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| I-X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| I-X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| I-X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| I-X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

Ukubekezelelana kweJomethri kwamapayipi e-SSAW

| Ukubekezelelana kwejometri | ||||||||||

| ububanzi bangaphandle | Ubukhulu bodonga | ukuqondisa | ukugqama | isisindo | Ukuphakama okuphezulu kobuhlalu bokushisela | |||||

| D | T | |||||||||

| ≤1422mm | >1422mm | <15mm | ≥15mm | ukuphela kwepayipi 1.5m | ubude obugcwele | umzimba wepayipi | ukuphela kwepayipi | T≤13mm | T >13mm | |

| ±0.5% | njengoba kuvunyelwene | ±10% | ±1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | '+10% | 3.5mm | 4.8mm |

Ukuhlolwa Kwamanzi

Ipayipi kufanele imelane nokuhlolwa kwe-hydrostatic ngaphandle kokuvuza ngomthungo wokushisela noma umzimba wepayipi.

Ama-jointer akudingeki ahlolwe ngamanzi, uma nje izingxenye zamapayipi asetshenziswe ekumaka ama-jointer zihlolwe ngempumelelo ngamanzi ngaphambi kokusebenza kokujoyina.

Ukulandelela:

Kumapayipi e-PSL 1, umenzi kufanele asungule futhi alandele izinqubo ezibhaliwe zokulungisa:

Ubunikazi bokushisa kuze kube yilapho kwenziwa ukuhlolwa ngakunye kwe-chmical okuhlobene futhi kuboniswa ukuhambisana nezidingo ezichaziwe

Ubunikazi beyunithi yokuhlola kuze kube yilapho kwenziwa ukuhlolwa ngakunye okuhlobene kwemishini futhi kuboniswa ukuhambisana nezidingo ezichaziwe

Kumapayipi e-PSL 2, umenzi kufanele asungule futhi alandele izinqubo ezibhaliwe zokugcina ubunikazi bokushisa kanye nobunikazi beyunithi yokuhlola yalelo payipi. Izinqubo ezinjalo zizohlinzeka ngezindlela zokulandelela noma yibuphi ubude bepayipi liye eyunithi yokuhlola efanele kanye nemiphumela yokuhlolwa kwamakhemikhali ehlobene.

Enye yezinzuzo eziyinhloko zepayipi le-SSAW ukuguquguquka kwalo ekukhiqizeni. Lawa mapayipi angakhiqizwa ngobukhulu obuhlukahlukene, ububanzi nobukhulu futhi angenziwa ngokwezifiso ukuze ahlangabezane nezidingo zephrojekthi ethile. Ngaphezu kwalokho, amapayipi ahlanganisiwe e-spiral submarine avame ukwenziwa ngensimbi esezingeni eliphezulu, okwenza angagqwali futhi aqinisekise impilo yenkonzo ende.

Ipayipi Lomugqa le-API 5L:

Ipayipi lomugqa we-API 5Liyipayipi lesakhiwo elisetshenziswa kabanzi elihlanganisa izingxenye ezingenalutho elihlangabezana nezindinganiso ze-American Petroleum Institute (API). Lawa mapayipi aklanyelwe ukuthutha uketshezi, njengowoyela negesi yemvelo, amabanga amade. Ipayipi lomugqa we-API 5L laziwa ngamandla alo aphezulu, ukuqina kanye nokumelana nezimo zemvelo ezimbi kakhulu.

Inqubo yokukhiqiza ipayipi lomugqa we-API 5L ihilela izinyathelo eziqinile zokulawula ikhwalithi ukuqinisekisa ukuthembeka kwayo. Lawa mapayipi enziwe ngensimbi yekhabhoni futhi anezakhiwo ezinhle kakhulu zemishini. Ukunamathela ngokuqinile ezindinganisweni ze-API kuqinisekisa ukuthi lawa mapayipi angamelana nokucindezeleka okuphezulu kanye nokushintsha kwezinga lokushisa, okwenza afaneleke ukusetshenziswa okubalulekile embonini kawoyela negesi.

Izinzuzo ezihlanganisiwe:

Uma ipayipi elihlanganisiwe elifakwe i-arc elingaphansi komhlaba kanye nepayipi lomugqa we-API 5L kuhlanganiswa, kunikeza ubuqotho nokuthembeka kwesakhiwo okungenakuqhathaniswa. Imisipha ejikelezayo yepayipi le-SSAW ehlanganiswe namandla nokuqina kwepayipi lomugqa we-API 5L yakha uhlelo lokusekela oluqinile lwesakhiwo.

Ngaphezu kwezinzuzo zazo, ukuhambisana kwepayipi elihlanganisiwe elifakwe i-spiral arc kanye nepayipi lomugqa we-API 5L kwandisa ukusebenza kahle kwamaphrojekthi epayipi. Ukuguquguquka kwepayipi le-SSAW kuvumela ukuxhumana okulula nepayipi lomugqa we-API 5L, okuqinisekisa ukugeleza koketshezi okungenayo imingcele ngaphakathi kwenethiwekhi yamapayipi.

Ekuphetheni:

Amapayipi esakhiwo anezingxenye ezingenalutho abaluleke kakhulu lapho kwakhiwa ingqalasizinda eqinile. Ukusetshenziswa okuhlangene kwepayipi le-SSAW kanye nepayipi lomugqa le-API 5L kunikeza ikhambi elinamandla elihlinzeka ngamandla, ukuqina kanye nokuthembeka kwamaphrojekthi ahlukahlukene. Kungakhathaliseki ukuthi kusekela izisekelo zezakhiwo ezinde noma ukuthutha uketshezi olubalulekile amabanga amade, la mapayipi adlala indima ebalulekile ekuqinisekiseni ubude besikhathi eside kanye nokuqina kwengqalasizinda yethu. Ngokusebenzisa amandla epayipi elihlanganisiwe elingaphansi kwe-spiral kanye nokuthembeka kwepayipi lomugqa le-API 5L, onjiniyela bangakha isisekelo esiqinile sekusasa elingcono.