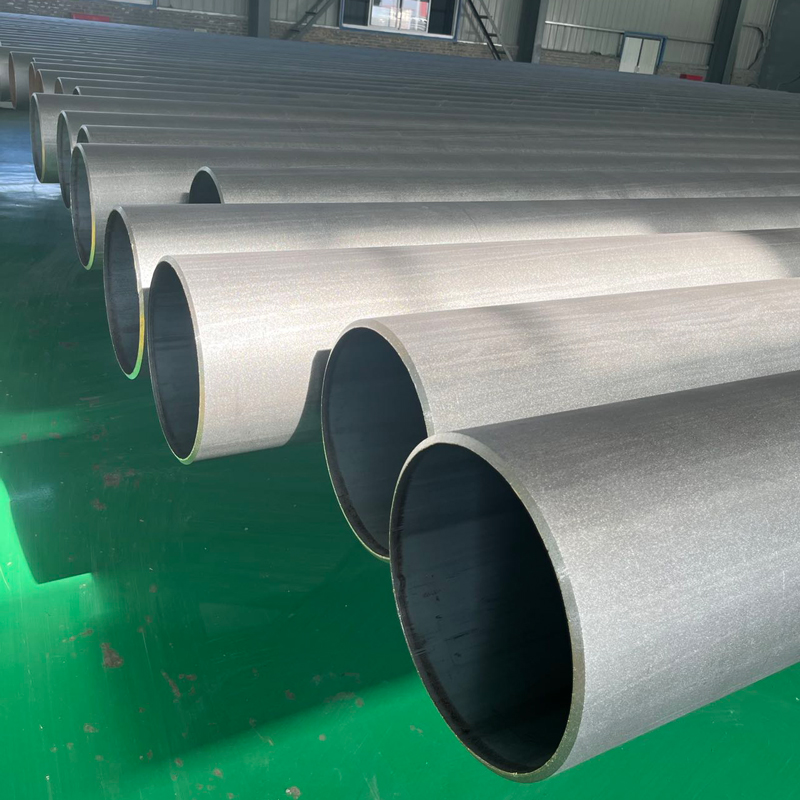

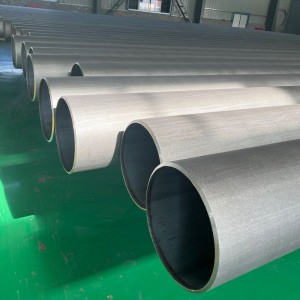

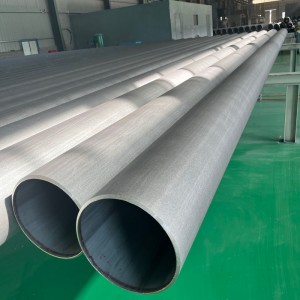

Izimbozo ze-Epoxy eziboshwe nge-Fusion Awwa C213 Standard

Izakhiwo zomzimba zezinto ze-epoxy powder

Amandla adonsela phansi athile ku-23℃: ubuncane obungu-1.2 kanye nobukhulu obungu-1.8

Ukuhlaziywa kwesihlungo: ubuningi obungu-2.0

Isikhathi sejeli ku-200 ℃: ngaphansi kwamasekhondi angu-120

Ukuhlanza okuqhumayo

Izindawo zensimbi ezingenalutho kufanele zihlanzwe ngokuqhumisa ngokuhudula ngokuhambisana ne-SSPC-SP10/NACE No. 2 ngaphandle kokuthi kuchazwe ngenye indlela ngumthengi. Iphethini ye-blast anchor noma ukujula kwephrofayili kufanele kube yi-1.5 mil kuya ku-4.0 mil (38 µm kuya ku-102 µm) okulinganiselwe ngokuhambisana ne-ASTM D4417.

Ukushisa

Ipayipi elihlanziwe kufanele lishiswe ekushiseni okungaphansi kuka-260℃, umthombo wokushisa akufanele ungcolise ubuso bepayipi.

Ubukhulu

Impuphu yokumboza kufanele ifakwe epayipini elishisiwe ngobukhulu obufanayo befilimu yokulungisa engaphansi kwama-millimitha angu-305 (305 μm) ngaphandle noma ngaphakathi. Ubukhulu obukhulu akufanele budlule ama-millimitha angu-406 (406 μm) ngaphandle kokuthi kunconywe umenzi noma kuchazwe ngumthengi.

Ukuhlolwa kokusebenza kwe-epoxy okungakhethwa

Umthengi angacacisa ukuhlolwa okwengeziwe ukuze kuqinisekiswe ukusebenza kwe-epoxy. Izinqubo zokuhlola ezilandelayo, zonke okufanele zenziwe emasongweni okuhlola amapayipi okukhiqiza, zingachazwa:

1. Ukubhoboka kwezingxenye.

2. Izimbobo zesikhombimsebenzisi.

3. Ukuhlaziywa kokushisa (i-DSC).

4. Ukucindezeleka okungapheli (ukugoba).

5. Ukucwilisa emanzini.

6. Umthelela.

7. Ukuhlolwa kokuhlukana kwe-Cathodic.