Izinzuzo kanye nokusetshenziswa kwamashubhu ahlanganisiwe e-Spiral embonini yanamuhla

Yethula:

Emikhakheni yobunjiniyela nokwakha ekhula njalo, ukusetshenziswa kweipayipi elihlanganisiwe eliyindilingaithandwa kakhulu. Lawa mapayipi aguquguqukayo futhi ahlala isikhathi eside angene ezimbonini ezahlukahlukene, okubonakala kuyisisombululo esishintshashintshayo sezinhlelo zokusebenza ezahlukahlukene. Kulesi sihloko sebhulogi, sizobheka ngokuningiliziwe izinzuzo ezimangalisayo ezinikezwa amapayipi ahlanganisiwe ajikelezayo futhi sihlole izinhlelo zawo ezahlukahlukene embonini yanamuhla.

Impahla Yomshini

| ibanga lensimbi | amandla amancane okukhiqiza | Amandla okudonsa | Ukwandiswa okuncane | Amandla amancane omthelela | ||||

| Ubukhulu obucacisiwe | Ubukhulu obucacisiwe | Ubukhulu obucacisiwe | ekushiseni kokuhlolwa kwe- | |||||

| 16 | >16≤40 | <3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

1. Iyini ipayipi elihlanganisiwe eliyindilinga?

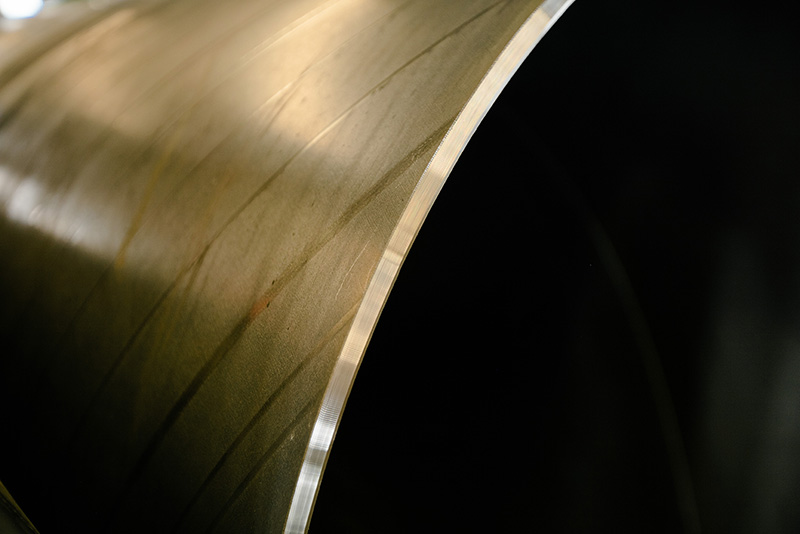

Ishubhu elihlanganisiwe elijikelezayo, njengoba igama lisikisela, ikhiqizwa ngokugoqa njalo insimbi bese iyishisela ubude bayo ukuze yakhe ipayipi elijikelezayo. Le ndlela yokukhiqiza iqinisekisa amandla nobuqotho obuphezulu, okwenza la mashubhu afanelekele ukusetshenziswa okudingakalayo.

2. Izinzuzo zepayipi elihlanganisiwe eliyindilinga:

2.1 Amandla nokuqina:

Inqubo yokushisela ejikelezayo ngokwemvelo inikeza ipayipi amandla aphezulu. Lokhu kuwavumela ukuthi amelane nokucindezeleka okuphezulu kwangaphakathi, imithwalo esindayo kanye namazinga okushisa aphezulu. Ngakho-ke, asetshenziswa kabanzi ezimbonini lapho ubuqotho besakhiwo bubaluleke kakhulu.

2.2 Ukumelana nokugqwala:

Ipayipi elihlanganisiwe elijikelezayo litholakala ngezinto ezahlukahlukene, okuhlanganisa insimbi engagqwali kanye nezinsimbi ezingagqwali. Ukumelana kwazo nokugqwala kuzenza zilungele ukusetshenziswa embonini yamakhemikhali, uwoyela negesi, kanye nokwelashwa kwamanzi. Zandisa isikhathi senkonzo futhi zinciphisa ingozi yokuvuza kanye nesikhathi sokungasebenzi.

2.3 Ukusebenza kahle kwezindleko:

Ukushisela okujikelezayo kunikeza izinzuzo zezindleko uma kuqhathaniswa nezindlela zokukhiqiza amapayipi zendabuko. Lokhu kungenxa yokuncipha kwesikhathi sokukhiqiza kanye nokuncipha kokusetshenziswa kwezinto. Ngaphezu kwalokho, ukwakheka okuhle kwamapayipi ashiselwe ngokujikelezayo kuvumela imiklamo eyenziwe ngokwezifiso kanye nezixazululo ezenziwe ngokwezifiso, okwenza izindleko zibe ngcono ngokunciphisa imfucuza kanye nesidingo sezesekeli ezengeziwe.

3. Ukusetshenziswa kwepayipi elihlanganisiwe eliyindilinga:

3.1 Izakhiwo kanye Nengqalasizinda:

Amapayipi ahlanganisiwe ajikelezayo asetshenziswa kabanzi embonini yokwakha, ikakhulukazi kumaphrojekthi amakhulu. Avame ukusetshenziswa ukudala izakhiwo zamakholomu, imisebe kanye nezinqwaba. Ngenxa yamandla ayo aphezulu, ingamelana nemithwalo esindayo futhi imelane namandla aseceleni, okwenza ifaneleke ekwakhiweni kwamabhuloho, izakhiwo eziphakeme kanye nezisekelo ezijulile.

3.2 Imboni kawoyela negesi:

Emkhakheni kawoyela negesi, amapayipi ahlanganisiwe ajikelezayo asetshenziswa kabanzi ekuthuthweni kwemikhiqizo kaphethiloli, igesi yemvelo kanye nolunye uketshezi. Amandla epayipi okumelana nezimo ezicindezelayo, ukufaneleka kokusetshenziswa olwandle olujulile kanye nokumelana nokugqwala kwenza kube ukukhetha kokuqala kwamapayipi, ama-risers kanye nokufakwa ogwini lolwandle.

3.3 Ubunjiniyela Bemishini:

Amapayipi ahlanganisiwe ajikelezayo asetshenziswa ngezindlela eziningi zobunjiniyela bemishini futhi avelele ngokuqina kwawo kanye nokuguquguquka kwawo. Asetshenziswa ekwenziweni kwemishini, izinhlelo zokuthutha kanye nezingxenye zesakhiwo. Ngaphezu kwalokho, adlala indima ebalulekile embonini yezimoto, enikeza ukwesekwa kwesakhiwo jikelele kuhlaka kanye nohlelo lokukhipha umoya.

Ekuphetheni:

Njengoba imboni iqhubeka nokukhula, isidingo sezixazululo eziqinile, ezihlala isikhathi eside futhi ezingabizi kakhulu siyaqhubeka nokukhula. Amapayipi ahlanganisiwe ahambisana ngempumelelo nalezi zidingo futhi aba yimpahla ebalulekile emikhakheni eminingi. Amandla awo aphezulu, ukumelana nokugqwala kanye nokusebenza kahle kwezindleko kuqinisa isikhundla sawo njengokukhetha kokuqala kwezinhlelo zokusebenza ezahlukahlukene zobunjiniyela. Njengoba siqhubekela phambili, kusobala ukuthi ipayipi elihlanganisiwe elihlanganisiwe lizoqhubeka nokubumba ikusasa lemboni yanamuhla.